Click here to open

Stops due to equipment breakdown are costly and reduce a company’s production capacity. The preventive maintenance program offered by LM 1947 provides experienced technicians who will track your equipment in order to minimize unplanned downtime caused by motor breakage.

In the medium term (six months to a year), you will see the effectiveness of our program; the performance and life of your equipment will considerably improve.

One of the important aspects of our preventive maintenance program is that it adapts to your needs. Each program is tailor-made according to the customer’s requests and integrates with all work environments. We can guarantee that every dollar invested by your company in preventive maintenance will be very profitable.

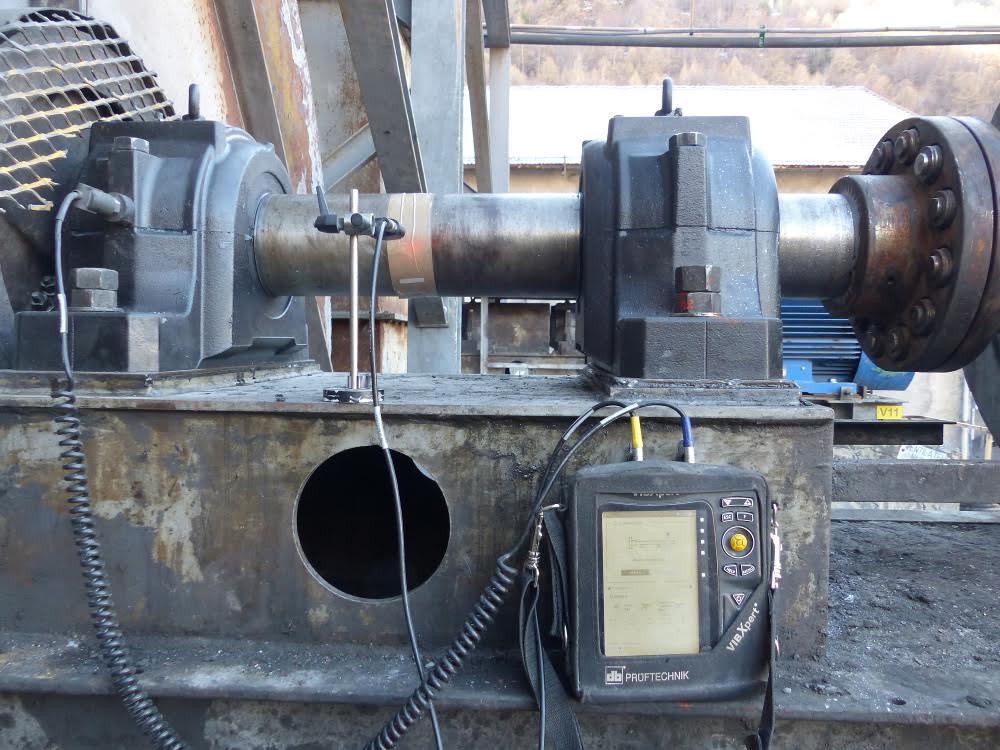

Vibration Analysis

Goal :

To put forward a machine health check and optimize maintenance. This analysis is very powerful and allows to get a precise portrait of the machine. However, to be effective, this analysis must be periodic (it allows the analysis of evolution). Vibration analysis is the most effective tool of preventive maintenance for rotating machinery.

Analysis Description

The vibratory signature found at various points of the machine makes it possible to determine its various defects:

- Misalignment

- Imbalance

- Rolling fault

- Failure of belts

- Gear problem

- Electrical faults

- Failure of fan blades or those of a pump

Advantages of a Vivration Analysis

- Limits damage by diagnosing faults before the failure;

- Extends the periods between two reviews;

- Optimizes maintenance schedules;

- Does not require stopping the machine;

- Determines the operating conditions of the machine.

For an optimal maintenance strategy

In collaboration with the maintenance and production department, LM 1947 lists the strategic motors of the company. Vibration monitoring is performed regularly. A complete expertise is made and a detailed report is given to the concerned department.

Imbalance causes significant dynamic efforts. It :

- greatly reduces the life of the bearings;

- increases energy consumption;

- increases the risk of stopping.

On-site balancing

We can perform dynamic on-site balancing on all your equipment (motors, fans, rotating machines …). This balancing is done at the request of the customer or when our vibration analysis shows a balancing defect.

LASER ALIGNMENT (CERTIFIED ISO 9001-2008)

A motor does not last long if its shaft is out of alignment with the machine it has to drive.

Rotating machinery shafts must be perfectly aligned to avoid mechanical breakage. Laser alignment greatly reduces the stress on bearings and axles. It allows motors to operate under optimal conditions.

50% of damages on rotating machines are caused by the misalignment of the shaft.

- Erratic alignment:

- Reduces bearings life;

- Generates vibrations;

- Increases the load and energy consumption;

- Increases the strain on the couplings, which increases the risk of overheating and breaking;

- Wears-off the joints, which causes infiltration;

- Causes production stops;

Even if you use flexible couplings, misalignment increases the load on the coupling and the level of vibration.

To effectively address this problem, LM 1947 uses the laser alignment technique. It combines precision, reliability and speed of execution.

This technique provides the necessary level of accuracy for modern machines.

Use our services to align your rotating machines. You will be sure to get fast and accurate alignments, according to the manufacturer’s standards.

The preventive maintenance services offered by LM 1947 are designed to support the reliability of your engineering. These services are rendered with the help of qualified technicians and resources needed to keep your motors and genset in perfect condition.

Our preventive maintenance services for AC & DC motors and gensets include:

- Laser alignment

- Cryogenic cleaning with “dry ice”

- On-site balancing

- Switch and ring service

- Replacement of filters

- Lubrication programs

- Equipment inspection

LM 1947 preventive maintenance services are designed to deliver measurable results with increased uptime and lower maintenance costs (laser alignment and on-site balance, for example, are proven ways to reduce bearing wear and unwanted heat build-up).

Once you have determined the trends and when your equipment is on the point of a curve towards failure, the preventive services come into play.

Your maintenance costs decrease as you make emergency purchases and experience unscheduled downtime in your planned service.

We can also help you reduce capital expenditures by extending the life of components.

LM 1947’s preventive maintenance also includes motor and genset inspections as well as end-of-warranty inspections so that you can take into account the results when making your repair or replacement decisions. These results provide significant improvements in your company’s productivity and return on investment.

OUR MANUFACTURERS

exclusive

exclusive